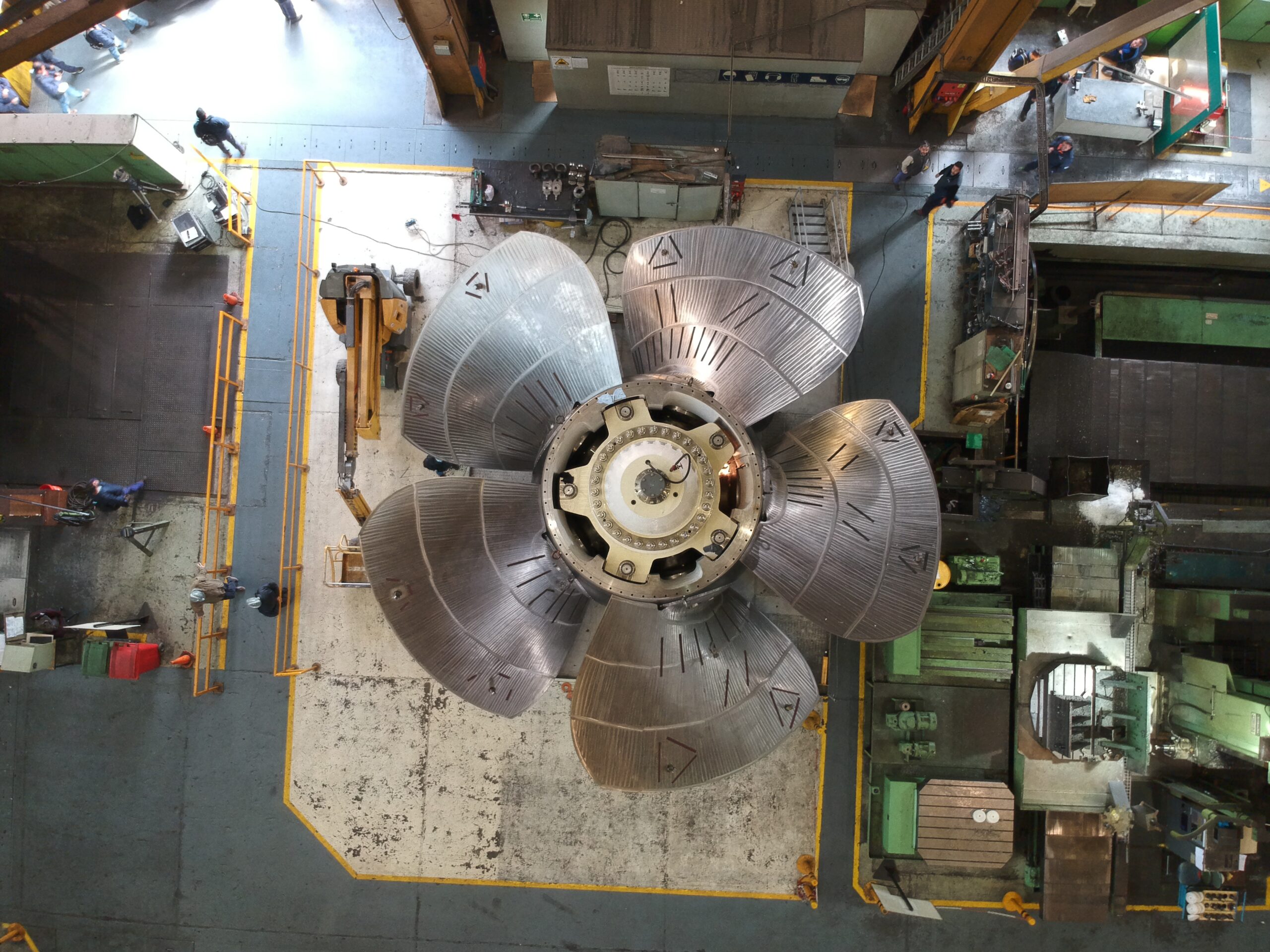

Large Structures

Manufacture of large structures involves the following processes: tracing and cutting, structure and welding, rolling and pressing, heat treatment, grinding, fitting and assembly, and sand- blasting and painting.

- Tracing and cutting with numerical control systems for maximum thicknesses of 300 mm for carbon steel and of 80 mm for stainless steel.

- Assembly, welding and grinding. Heavy lifting capacity with a 35-meter gauge 250-ton bridge crane.

- Sand-blasting and painting. The sand-blasting area is 22 mm long, 12 mm wide and 8 mm high.

- Heat treatment in two 7x7x15 m furnaces.

- A 1,000 t press with a 4×2 m wide table and a gantry system for handling of parts.

- A 4 m wide four-roll plate rolling machine capable of rolling thicknesses of more than 100 mm.